Padding

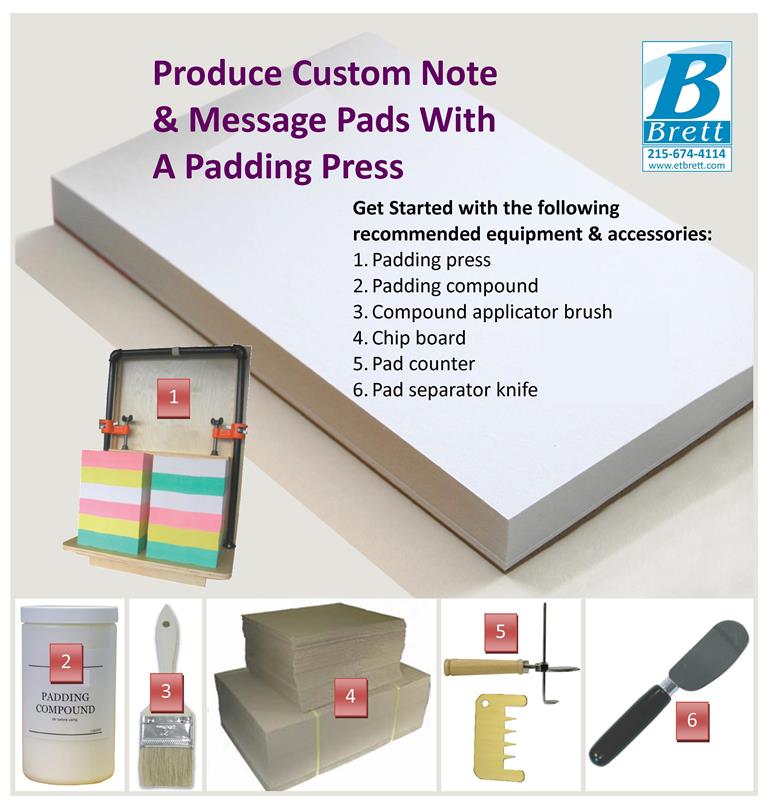

Create easy peel-off message pads, note pads, form pads and multi-part form sets with a padding press. A padding press allows you to squarely stack your forms against an alignment panel, then press the stack with a secure clamp bar. Once your forms are stacked and clamped you then remove the alignment panel and apply the padding adhesive with a brush. Padding presses are available in small bench top configurations to large floor standing models.

Create easy peel-off message pads, note pads, form pads and multi-part form sets with a padding press. A padding press allows you to squarely stack your forms against an alignment panel, then press the stack with a secure clamp bar. Once your forms are stacked and clamped you then remove the alignment panel and apply the padding adhesive with a brush. Padding presses are available in small bench top configurations to large floor standing models.

When greater production of pads is required automatic padding equipment is available. Cold padding adhesive is available for brush-on padding and a specially formulated hot-melt adhesive is available for automatic padding machines.

Padding accessories include paper joggers, paper carts, pad counters, padding brushes, padding knives and chip board.

Multi-part form production is created using carbonless paper and Fan-Apart Adhesive. The Fan-Apart Adhesive only attaches itself to the treated side of the carbonless paper. When the adhesive dries you release the padding press clamp bar and simply "Fan-Apart" the stack of forms causing separation at the non-treated side of the carbonless paper, creating individual multi-part sets.

-

Choose the product options first

A convenient turn style base of the Handy-Padder allows the operator to load, clamp and pad from a single position.

-

Choose the product options first

Put away your bricks, blocks, and boards. The Mini-Padder design provides a portable and compact table-top padding device for the right price.

-

Choose the product options first

Best Built Padding Press In The Industry!

-

Choose the product options first

Pad two stacks of 5,000 8.5" wide sheets side by side.